Industrial marking in the iron and steel sector

Industrial marking for different applications in the iron and steel industry

MARKING TECHNOLOGY

Dot peen

Scribe

Silent, effective marking that uses a tungsten carbide or diamond needle, providing a precise, deep result.

Laser

MARKING IN THE IRON AND STEEL SECTOR

Something we have learned full well in industrial development is that we must always track all parts and components of machinery we use, as well as the objects that it produces. For this reason, duly marking metal is one of the most effective and most common procedures while producing different parts.

Thanks to this tracking, you can precisely determine how effective each part or element is and have a pertinent safety measure in the event of loss, defect, or failure.

In the steel and iron industry, with the materials it works with, this tracking is crucial.

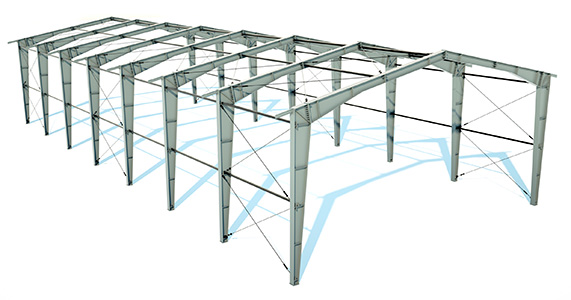

PARTS FOR THE IRON AND STEEL SECTOR

What does marking metal parts consist of?

Marking metal parts consists of a process where one engraves or marks the material with a series of data, either in text or numerical format, which gives different information on the manufacture of the part.

Marks can be made on different kinds of materials. However, in the iron and steel industry, marking on stainless steel and marking on metals like gold, for example, are processes that have become standardised.

Metal marking techniques

At Couth, we manufacture marker machines with different metal marking and stainless steel marking techniques:

- Dot Peen Marking. This is a metal mark that uses a technique with impacting dots on the surface of the metal. This technique provides a precise engraving with excellent legibility on the part.

- Scribe Marking. With a tungsten carbide or diamond needle, this marks metal parts, alloys, and even certain kinds of resistant plastics, making fine, highly precise incisions. This is also a silent marking system.

- Laser Marking. One of the most novel techniques used in the metal marking industry in iron and steel, especially for serial productions. This uses a laser to precisely engrave the material. The huge advantage is its durability over time and while using the part.

Importance of marking metal in the iron and steel industry

Marking stainless steel, as well as marking metal for parts like gold ingots, is currently an essential step, both in the iron and steel industry, and in manufacturing and assembly processes.

For example, this action of marking metal parts can provide a huge amount of information that acts not only for traceability of the company that made the product, but for the entire life cycle of the part, from distribution to final use.

What can a code marked on a part include? Varied information that will depend on the part itself: the date it was made and its expiry, the batch and serial number, and other important characteristics to include in the mark.

Types of identification used in metal marking

There are many ways to identify materials and parts. In recent years, this technology has also evolved to adapt to current needs in each sector. Some of the most widely used are:

- One of the most popular on the market. With its bar-and-space design, it stores encoded information that can be read with a specific reader. One of the most recent ways to mark is a QR code.

- Datamatrix Code. Very similar to a barcode, except that its two-dimensional system provides greater information storage capacity.

- DPM or Direct Part Marking. This system makes individual and permanent marks for the characteristics of this particular part. This provides greater traceability throughout the entire life cycle.

The future of the iron and steel industry in marking metal parts

In an increasingly globalised world with high consumption levels, marks for stainless steel and other materials are improving and becoming more specialised day-by-day.

With technology on the rise, greater access to it, and interconnectivity, we will be seeing better techniques in the future to guarantee not only the process, but also the durability of the marks and, consequently, their information and usefulness throughout the entire industrial production system.

At Couth, as experts in metal marking, we offer the best solutions for your needs.