Rail

Industrial marking for train parts

MARKING TECHNOLOGY

Dot peen

Speed, mark depth, and reliability . The technology they use makes them the fastest on the market.

Scribe

Silent, effective marking that uses a tungsten carbide or diamond needle, providing a precise, deep result.

Laser

COUTH laser marking is high-speed. The stability of its output power provides high, long-lasting performance over time.

SECTORS

MARKING IN THE RAIL SECTOR

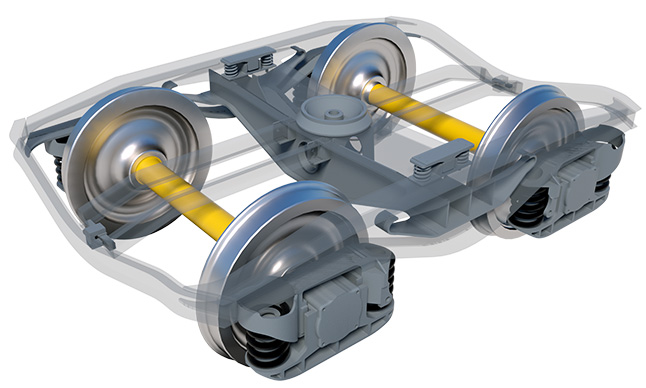

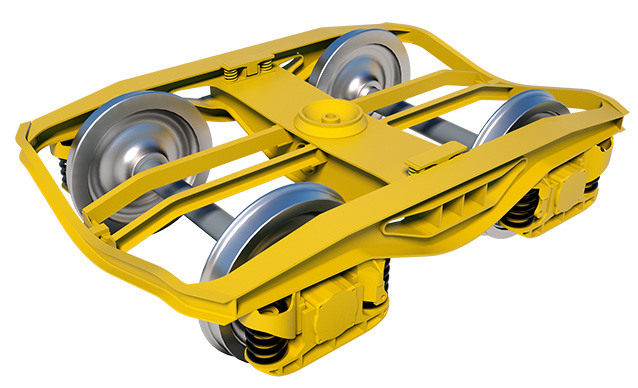

COUTH® provides the marking solution for different applications in the rail sector. In this sector, the depth of the mark is one of the most important requirements, given the great force to which the different parts are subjected, especially fatigue.

PARTS

PARTS FOR THE RAIL SECTOR

VIDEOS