Marking and Traceability for Automobiles and Car Parts

Marking automobile parts

MARKING TECHNOLOGY

Dot peen

If you’re looking for speed, a deep mark, and reliability, this is your best option.

The built-in technology makes it the fastest on the market.

Scribe

When you need a silent and effective method, the scribe method for marking automobile parts is a must-have.

It uses a diamond or tungsten carbide needle for a precise, deep results that would be difficult to achieve otherwise.

Laser

Automobile marking with the COUTH® laser is known for its high speed.

Thanks to its stability and output power, it gives the part a high-performance result that is long-lasting over time.

Marking automobile parts is one of COUTH®‘s specialities, exponentially improving traceability in the automobile sector.

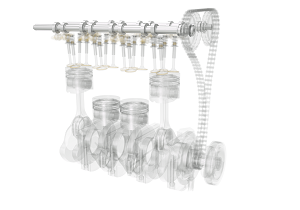

Since automobile parts come in a wide variety of different sizes, shapes, and materials, they are manufactured in large batches. This is precisely what makes it difficult to establish an optimum industrial traceability system. So, what are the solutions?

COUTH® applies different marking solutions: dot-peen, scribe, and laser. This way, depending on the part, we use the right mark, individually identifying each one of the parts made.

SECTORS

MARKING IN THE AUTOMOBILE SECTOR

In our search to obtain optimum traceability systems for the automobile sector, COUTH® is specialised in offering different industrial marking solutions for automobile parts.

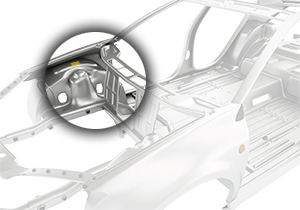

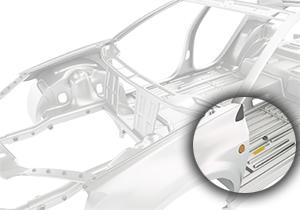

One of the main objectives is to ensure perfect legibility for the mark, even after the parts have gone through repair or painting treatments.

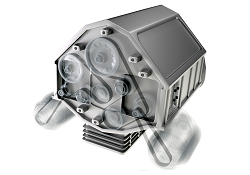

We also seek to extend these capacities to the entire vehicle, from the vehicle’s structural elements to the wheels, also including the engine parts.

PARTS

PARTS FOR THE AUTOMOBILE SECTOR

VIDEOS

MORE ABOUT MARKING IN THE AUTOMOBILE SECTOR

The best way to explain COUTH®‘S work with marking automobiles is by showing how the different marker tools work.

Would you like to improve your traceability in the automobile sector? Watch these videos we have selected for you and learn how a specialised company like COUTH® works.

Advantages of marking automobile parts

After discussing work processes, areas of application for industrial marking in automobiles and kinds of marking technologies, it is time to highlight some of the added advantages and benefits of applying these techniques to business and traceability.