If you are in search of an industrial marking system that suits the particular needs of your company, finding out the aspects that you should consider when choosing the ideal marking machine is a must.

It is important to be aware that there are several processes for industrial marking that use different techniques for engraving numbers, logos, text, images, etc., the reason why you should base your decision on the characteristics, type, requirements and magnitude of the project when selecting the appropriate machine.

Couth are specialists in a range of industrial marking with state-of-the-art equipment that incorporates innovative processes to achieve the best results.

This post aims to help you choose the marking machine that represents the best solution for the specific requirements of your company according to the type of product and work material.

The importance of product marking

Knowing how to choose an efficient marking machine contributes to obtaining greater control and easy identification of your products.

This type of permanent marking systems also offers significant benefits for a company, representing major savings in terms of time, effort and resources.

The marking of products includes relevant information such as the production and expiration dates, serial number, batch, and other important data.

Products that are not marked or coded properly can result in errors and order returns, leading to significant losses, both in terms of money and time. Therefore, it is necessary to choose a marking machine that represents an effective solution for the marking and coding of your products.

There are presently a large number of specialised systems for all kinds of industrial marking and engraving using several methods that are a significant contribution in the production process, thanks to how they optimise the profitable use of resources and parts, since they allow traceability and control, from the start of production until they are delivered to distributors and customers.

Types of industrial marking

Before choosing a marking machine, it is important to be aware of the different industrial marking and engraving techniques available, which can be suitable for different projects depending on the specific materials and needs. That said, the types of industrial marking include:

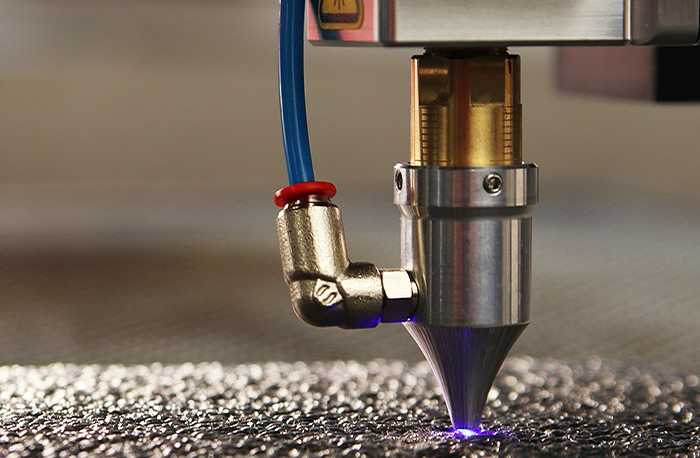

Laser marking

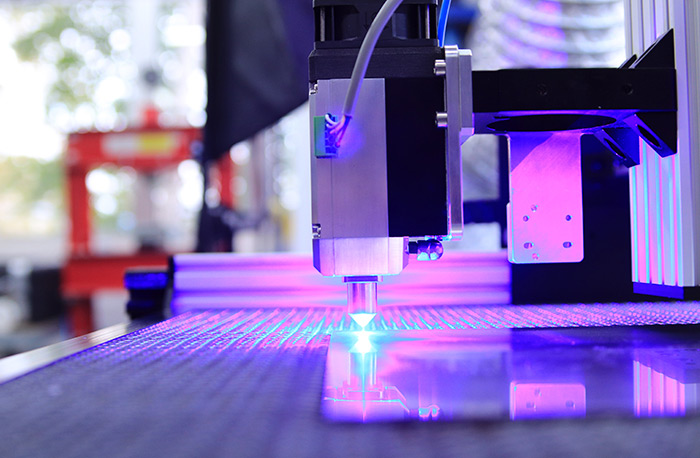

The laser marking and engraving method uses advanced technology and offers highly effective results for various industrial processes with high production volumes.

It can be applied onto a wide variety of materials, such as iron, stainless steel, copper, aluminium, brass, leather, ceramics, certain plastics, glass, etc., which is a fundamental aspect when choosing a marking machine.

It allows marking to be made on a variety of QR codes, images, alphanumeric characters, datamatrix codes, among others, guaranteeing the identification and traceability of each of the parts produced.

Some of the benefits of this method are:

- High quality in terms of accuracy and readability.

- Flexibility to adapt to complex surfaces.

- Intuitive software.

- Low maintenance.

- High resistant and durable equipment.

- Silent and fast process.

- Permanent results.

- Allows you to customise the content, including adding colour to it.

- Increases control over process security actions.

Scratch marking

This marking is obtained silently through the application of a punch or carbide or diamond tip, which exerts pneumatic pressure on a certain surface, efficiently engraving logos, characters and QR codes.

Its main benefits include:

- High quality for sharp, accurate results.

- Fast process and very low noise levels.

- Low-cost maintenance.

- Its technique enables the sharp marking on metal surfaces, alloys and hard plastics.

Micro-percussion marking

Industrial micro-percussion engraving incorporates technology that allows you to achieve optimal results quickly with a high level of efficiency and productivity.

This method uses an oscillating marking tip that is applied to certain surfaces to engrave the data through alphanumeric characters, logos, symbols, codes, texts, dates, etc.

It is a method widely used in sectors such as automotive, steel industry, aeronautics, power generation, railway, profiles, etc. and many more.

The benefits of this method include:

- Allowing the marking depth to be regulated according to the material.

- Applicable on metal surfaces, alloys and plastics with a high degree of hardness.

- It is effective on parts with a range of shapes, such as cylindrical or flat ones.

- It does not require any consumer material, as the only wear takes place on the marking tip.

- Minimal maintenance.

- It is very useful for the marking of machined parts, aeronautical components, automotive, to name a few.

CNC industrial engraving

This method consists of a metal marking that is controlled numerically, therefore requiring CNC machines that manage the process from a computer.

- It allows fast and efficient high-quality results to be obtained, which are adjusted to mass production processes.

Electrochemical engraving and marking

This is suitable for engraving on conductive metal surfaces, due to the electrical current and electrolytic fluids used, by means of a marking head which releases a slight current on the metal using a stencil or marking template.

- This type of marking offers fast and effective results at low cost. It can also be used in a wide variety of environments and operating systems.

- It is very effective when applied on stainless steel surfaces.

The best tips for choosing a marking machine

It is essential to define key aspects when choosing a marking machine that meets the specific needs of a company, such as marking speed, its capacities, precision, durability, dimensions, resolution, maintenance, and budget, therefore making it a good idea to do the following:

Identify the materials to be worked on

It is essential to be aware of the materials you will work with frequently, since this aspect represents the key to choosing a marking machine that is suitable for your company’s needs.

Although these are machines that offer great versatility for marking on various materials, not all surfaces are the same. Shapes and characteristics can vary considerably, such as flat, cylindrical, square, etc., therefore choosing the equipment that offers and guarantees the best results by adapting to the specific conditions of the material and its surface.

Depending on the power, efficient marking and engraving can be made on materials such as: Stainless steel, aluminium, rubber, titanium, plastics, carbon steel, silver and gold, to name a few.

Determining which traceability needs are required

Another basic aspect of choosing a marking machine is to specifically define the traceability needs required by the project.

A company requires a system that allows it to identify the entire process related to a product from its production, how long it remains internally and its dispatch or sale before arriving to distributors or customers.

Here is where assignment of batch numbers that identify each part plays a fundamental role, which must be included in all related documents such as labels, delivery orders, invoices, among others.

Defining the types of markings

It will be necessary to determine what kind of marking will be applied to the engraving, which is also an essential aspect for choosing a suitable marking machine.

The marking of codes, alphanumeric characters, images, text, and many other data may be required, therefore making it necessary to define a format for the mark that will be applied on the parts and products. Several models may also be required for the different sizes and particular characteristics of each piece.

For all these reasons, an industrial marking machine must offer the capabilities and flexibility necessary to meet the requirements of the company.

Marking machine type

When choosing an efficient marking machine, you must also take into account its size and the space available to place it in.

It involves integrating a number of features necessary to determine which marking machine is ideal for your needs.

The space where it will be located must be defined, to choose a marking machine that has the most suitable measurements, weight and size.

This type of machine can be compact and robust, and its built-in technology can also influence these characteristics.

Capabilities and functionalities

Other tips for choosing a marking machine that fits the specific needs of a project are identifying if the process can be automated or if the data needs to be designed and edited on the device marked.

Keep in mind that certain types of industrial marking allow you to customise the information, even adding colours and other more basic ones, which is influential when making the decision to purchase the machine.

Laser, scratch and micro-percussion marking models allow them to be perfectly integrated into production lines.

Production volume is one of the factors to bear in mind when choosing a marking machine, since certain equipment can provide acceptable production capacities, while others are specifically designed to cover massive productions.

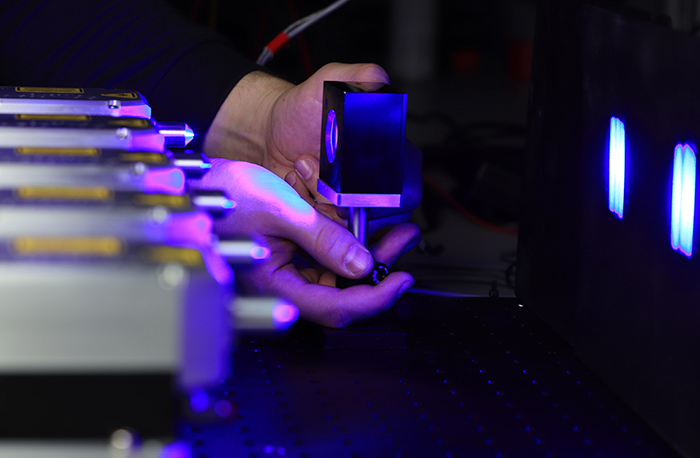

Ensuring the best security controls

Industrial marking machines aim to facilitate the identification and control of each part produced, as well as improve security controls to prevent the counterfeiting and fraud of engraved products.

Some of these models are more efficient for security control, such as laser marking equipment, which is applied during the production of bank cards, ID cards, and many more.

Budget

Budget is another of the essential aspects to choose a marking machine, since it must take into account both the needs and the possibilities for the investment when purchasing the equipment.

There are a variety of high-quality industrial marking equipment options available that offer excellent results. Many of them require little maintenance, representing significant savings. However, it is important to be aware of how much their value goes up as they incorporate more technology and power to offer high production volumes.

It is important to define the specific production needs in order to assess the cost required for the investment when purchasing equipment that meets the requirements of the company, taking into account the benefits of having an efficient industrial marking machine.

Technical support

Another aspect that cannot be overseen when choosing a marking machine is technical support.

While this equipment does not require further maintenance, it is important to be able to avail of efficient technical support that provides the training to learn how to operate the industrial marking equipment, achieving its highest performance, as well as to resolve any doubts in a timely manner.

Find the best industrial marking machines in Couth

Couth has more than 65 years’ experience in the sector and the best equipment available. Our technical support specialists are also highly qualified to answer all your questions and help you choose a marking machine that suits the needs of your company through an efficient and profitable investment.

We have a range of models allowing you to choose the one that best suits your industry according to their technical characteristics, either depending on its size, functionalities, power, placement of the equipment in the production line, which are aspects that will be considered when you seek advice.

We offer highly efficient solutions for industrial marking using laser, scratch and micro-percussion equipment. We can also design customised solutions according to your specific needs.

Our management model is based on Standard UNE-EN ISO 9001, where the principles of Continuous Improvement, Leadership, Customer Guidance, Effective Communication and Evidence-Based Decision Making prevail.

If you need to choose a marking machine that is effective and accessible, do not hesitate to contact us to allow us help you find the best solution to your needs.