Laser engraving is one of the main and most remarkable techniques used in marking today. But how does laser engraving work, what benefits does it offer and what kind of materials can we mark? In this post, Couth will tell you everything you need to know about it.

What is laser engraving?

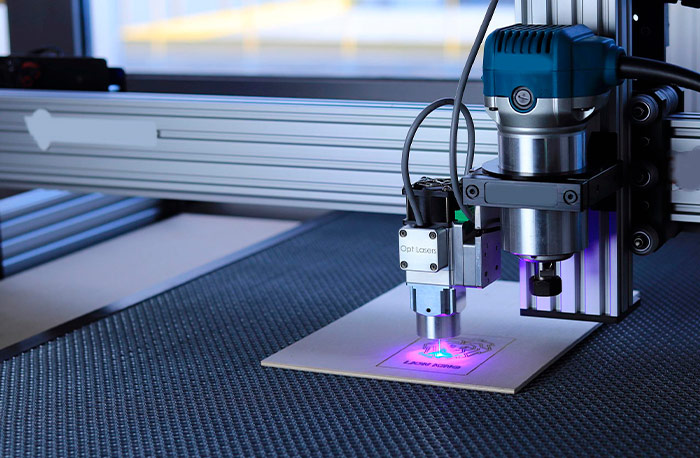

Laser engraving involves the use of a subtractive-type technique,

where a focused laser beam that basically heats or vaporises the material is used.

Marks are left with a varying degree of depth in terms of exposure time, with a contrasting colour on the surface that lasts over time.

How does laser engraving works?

As we explained earlier, the actual engraving process is not complicated. To find out how laser engraving works, the first thing involved in the process is determining the material and design to be engraved.

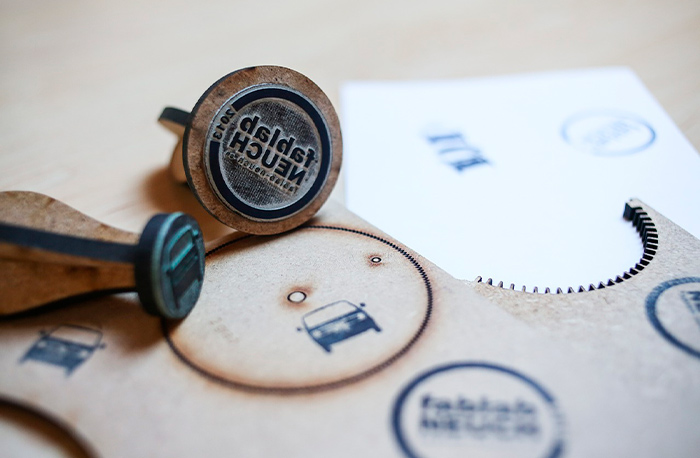

Bear in mind that engraving can be diverse and adapted to the industry that needs to use it. This can range from bar codes, serial numbers, datamatrix or others used for product traceability, to logo engravings for advertising, and even ones that are more customised, such as images or signatures.

Once we know the design and material to be engraved, the process begins, where the beam is projected on the surface that will burn the desired pattern on it, thus obtaining very clean and precise finishings.

Vector laser engraving and rasterisation

Although laser engraving is thought to involve only the projection of the beam of light, the beam can actually do this in two ways during its work: vector or rasterisation.

Rasterisation refers to the process that uses curves and lines drawn one after the other to construct the desired pattern. All of this takes place at the same time.

Vector engraving, on the other hand, allows line-by-line as well as point-by-point engraving. This is the most widely used technique for complex images or even shapes or letters that need to be filled in.

What kind of materials can be laser engraved

One of the benefits of knowing how laser engraving works is that this technique is applicable to different materials, hence its versatility and preference of use.

Engraving refers to a wide variety of these when it comes to plastics: ABS, acrylic, rubber, foam, polycarbonate, polyester, polypropylene and polyurethane.

One important limitation is how the use of laser is not recommended with materials such as PVC, since this would generate a gas that could become toxic.

How does laser engraving work in relation to harder surfaces such as metal? Certain metals are more “friendly” when using laser. These include stainless steel, aluminium and anodised aluminium, copper, brass or even titanium.

One limitation with some of these materials such as stainless steel and titanium is the necessity to use an additive to achieve the contrast required by the laser.

A final point worth mentioning is other surfaces that are suitable to receive laser marking. These include paper, cardboard and cardboard, leather, cork, glass and mirrors, wood, marble, ceramics, stone, slate and even fabric.

An important point during the process is to determine the strength, depth and time of exposure to the laser. Making an engraving on rubber, aluminium, cardboard or stone is not the same thing. Each one has a different level of resistance, something that should be borne in mind during the laser process.

As we see a very wide range of areas covering different industries. All benefited from a system as flexible as laser engraving.

Benefits of choosing laser engraving

Now that we have explained what it is and how laser engraving works and the materials that are often used, the benefits of using this technique are already beginning to become clearer. However, it is worth mentioning some other benefits that will help convince you about the usefulness of laser engraving.

Versatility of use

We have already pointed out the wide variety of surfaces that can be engraved with laser. A laser machine is almost universal for all kinds of industries.

Contactless processing

Another great benefit of laser engraving is how the machine as such has no contact with the engraved material. It simply projects the light beam from the recommended distance, without direct handling and rubbing that can cause damage, leave a lot of residue or even damage your tools.

Minimal waste

One of the major benefits of laser engraving is the minimal residue generated by the process. As the surface is heating up, minimal residue, such as chips, dust, etc., is generated.

Precision and detail

How does laser engraving works on images and text? Very well.

One of the major benefits of laser are the high-quality results obtained. Very defined “prints” can be made, making it possible to engrave different subjects, from numerical series to photographs.

More economical

One thing that industries using laser engraving as their marking technique love is how accessible and very economical it is.

The use of laser engraving is a cost-effective investment that allows it to be used on a minimal scale, as well as on large batches of products.

Saving on time

One last point about the many benefits of laser engraving is its speed. Although the designs are more complex, the whole process does not take much time, which involves savings in every regard, not only in terms of time, but even more so in money.

Couth laser engraving machines

When it comes to the perfect laser machines for your business, the machines manufactured by Couth are just the right one for you. Our Couth Laser Pro or Max engravers are the most versatile for use in different types of processes or projects.

We adapt to your needs and provide quality equipment. Even the software is easy to use, is very intuitive and has fantastic results for all kinds of graphics.

Contact us for any query you might have about the ideal laser machine for your company or enterprise.