Industrial marking is becoming increasingly necessary, and Couth is fully aware of its requirement to meet the demands of manufacturing and production companies. Therefore, it offers each of its customers just the right marking system for each type of material and part.

If you are looking for a company specialised in industrial marking and traceability, Couth offers you top-quality tailored solutions with state-of-the-art equipment and innovative processes capable of offering just what each customer needs.

MARKING AND INDUSTRIAL TRACEABILITY

We are specialists in marking and industrial traceability. We offer reliable, innovative, and customised solutions to meet our clients’ industrial marking needs. Our close relationship with the client means we can identify their marking needs.

COUTH® provides high-value proposals, maximising productivity at production plants, with the speed, quality, and efficiency of our dot peen, scribe, and laser products.

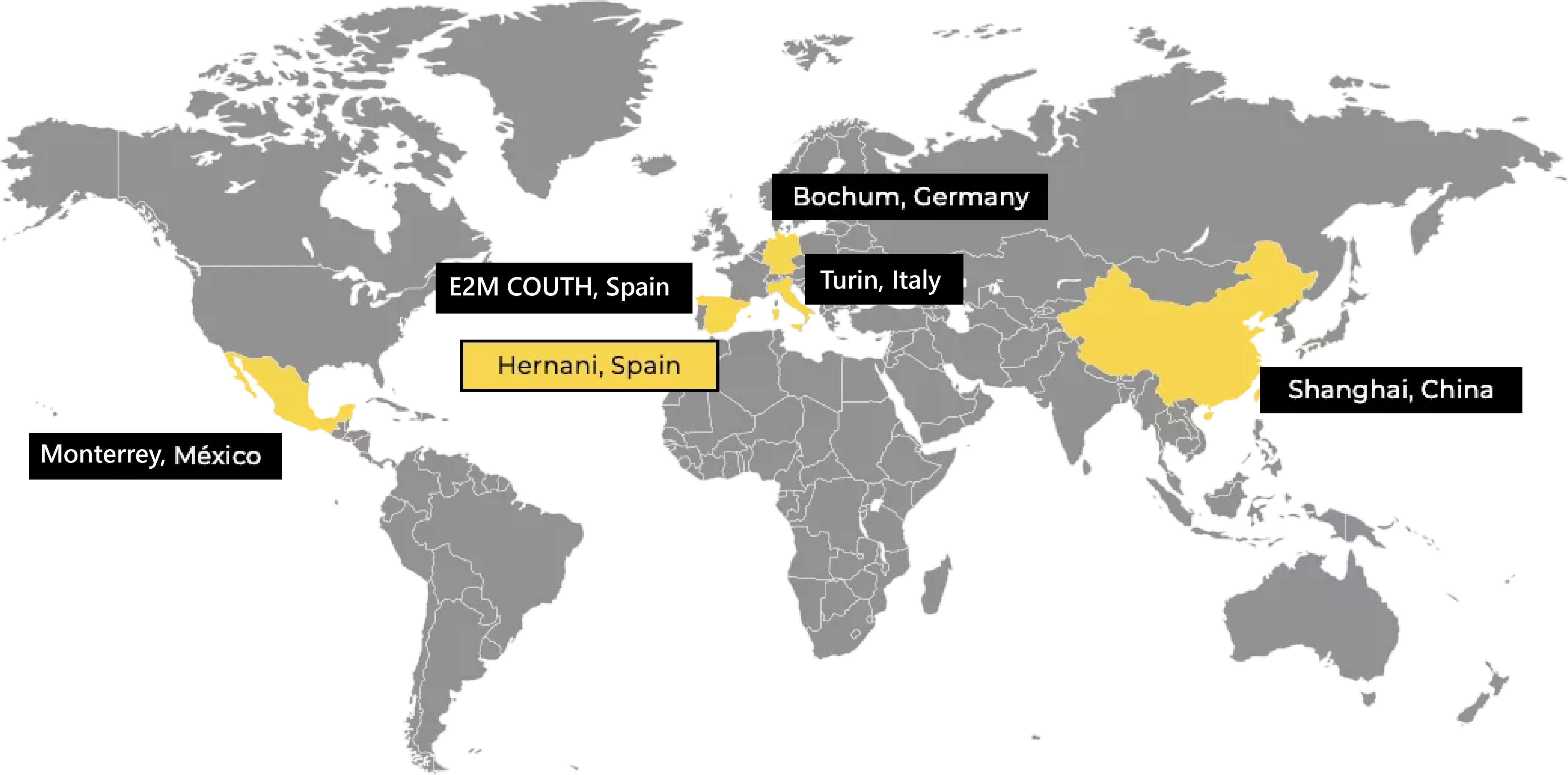

Our own technical support service, our five subsidiaries, and a wide network of official distributors covering more than 66 countries allow us to meet our clients’ and users’ needs.

We are specialists in industrial marking

COUTH Performance TOP Performance

Automobile

Aeronautic

Rail

Iron and steel

Gas and oil

MARKING AND INDUSTRIAL TRACEABILITY

5 Subsidiaries | 66 countries | 35,000 machines in operation

Our industrial marking value proposition

COUTH guarantees maximum efficiency in all the products it offers, with fully effective unbeatable results. Our industrial marking systems offer:

- Maximum

- Speed in all types of marking processes.

- Quality during the process and in the result.

- 100%

Technology tailored to your needs

Whether your industry requires laser marking, scratching or micro percussion, we at Couth can provide you with the equipment that suits your needs according to your type of product or work material. We advise you to be able to select the right one and to allow you to make a smart, efficient and profitable investment.

Couth will look for a tailored solution for you and your industry for any specific technical needs you may have. We create solutions without having any heed to obstacles, because each challenge presents an opportunity to grow alongside our customers.

Practical, fast and noise-free equipment

If there is one thing that characterises our industrial marking equipment, it is how highly effective they are for the demands made today, performing high quality jobs on every material that is used.

Demand is currently very high, making time a precious commodity, something our industrial marking must respond to. Each Couth machine guarantees a very fast and perfectly sharp marking, capable of giving a flawless appearance to all kinds of materials, ensuring ideal reading and traceability at all times.

The beauty of industrial marking is found not only in its speed and sharpness, but also in how quiet it is. We are very aware of how important it is for this type of process to not add any noise pollution to our activity.

What does Couth offer its customers?

We offer top-class support during the consultation and decision-making process for your industrial marking equipment. We also have technical support specialists who are always ready to answer your questions.

Our five international subsidiaries along with our extensive network of distributors in more than 66 countries allow us to reach every customer to meet every request first hand in the shortest time possible and overcoming any type of barrier.

One-to-one attention in your industrial marking requirement

If you are looking for innovative, truly efficient industrial marking solutions that meet your needs now and in the future, Couth is your industrial marking company. Because your company and products are unique and deserve the attention our specialists can offer.

Don’t wait another minute-book your consultation today and solve your industrial marking needs by working alongside Couth.

BLOG

LATEST PUBLICATIONS

New Couth Headquarters

We are pleased to inform that, due to the continuous growth of the company since our beginnings 70 years ago in Hernani, the time has come to have adequate facilities to continue...

Differences between mechanical engraving and laser engraving

When discussing the differences between mechanical and laser engraving, it is important to highlight that they are two popular methods to create permanent marks on a wide variety...

Steps to engrave a QR code on metal

In industry, it is more and more common to see QR codes engraved on metal for different parts, especially because of their unlimited capacity to store information in a reduced...

WHAT DO YOU WANT TO MARK?